CASE STUDY

Tankering V Water treatment

Construction

CLIENT

Civil Engineering Firm

LOCATION

England, UK

SERVICES

Water management review

Fluid analysis

Supply of water treatment equipment

Commissioning and training

THE CHALLENGE

A civil engineering site in England faced a significant challenge managing surface water run-off containing high levels of suspended solids—primarily fine clay particles with slow settling characteristics. Left untreated, this run-off could not be legally or safely discharged, posing both environmental and operational risks.

HOW WE HELPED

Following an initial site visit and consultation, Osso conducted a detailed assessment of both surface and groundwater on site. Water samples were taken for analysis, which confirmed the presence of slow-settling, clay-based solids that could not be effectively removed through passive settlement alone.

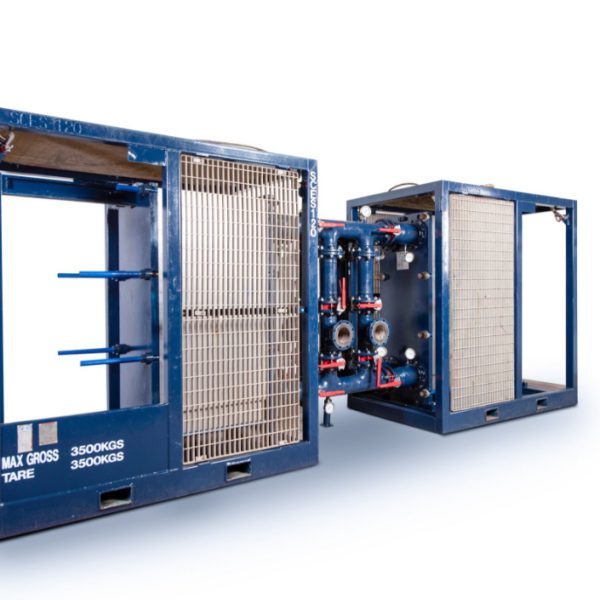

To address this, Osso recommended the deployment of our WTS20 water treatment system, incorporating proportional chemical dosing to accelerate solid separation and ensure compliant discharge quality.

Alternative options available to the client were limited. The only viable fallback would have involved regular off-site tankering of wastewater to a licensed disposal facility—an approach associated with high operational cost and environmental impact.

"It worked brilliantly. We even pushed 90 m an hour through it at times and still got clean water coming out…. In comparison with other dewatering options, Osso water treatment systems are a far more efficient and cost-effective solution.” |

RESULTS

The client opted for the on-site course of treatment and we commissioned the WTS20. Throughout the duration of the groundworks phase, the unit met the site’s treatment demands effectively—handling both ground and surface water inflows without interruption or performance issues.

Over the course of 840 days, the WTS20 unit treated 20,760 m³ of silty water. In comparison, removing this volume via tankers (assuming a 30 m³ capacity per vehicle) would have required approximately 692 tanker movements—equivalent to nearly two tankers per day. This would have significantly impacted local traffic and generated considerable CO₂ emissions.

In terms of financial impact, the estimated cost of tankering and disposal would have been £800k. By contrast, hiring the WTS20 unit delivered an 84% cost saving, as well as clear environmental and logistical advantages.

- Successfully treated 20,760m³ of silty water

- Eliminated the need for 690+ tankers

- £800k+ of savings recognised with this approach

- Significant environmental and logistical improvements recognised

CONTACT OSSO

Got a question

about a project?

Related Case Studies

Geothermal drilling achieving a 25% temperature reduction

- 25% temperature reduction

- Full-service maintenance contract

- Annual equipment swap out and refurb programme

Improve drilling efficiencies in high temperature wells.

- Reduced days drilling NPT per section drilled

- 40% decrease in round trips per section drilled

- 95% reduction in tool DBR