CASE STUDY

Oil Terminal - Tank Decommissioning

Oil & Gas

CLIENT

Operator

LOCATION

Scotland, UK

SERVICES

Survey

Testing

Mechanical Separation

THE CHALLENGE

Located in the Northeast of Scotland an operator required the full decommissioning of an oil tank. This involved stringent risk assessments, including a Control of Substances Hazardous to Health (COSHH) to ensure safe operations. A collaborative and consultative approach was key to understand the specific needs of the operator.

HOW WE HELPED

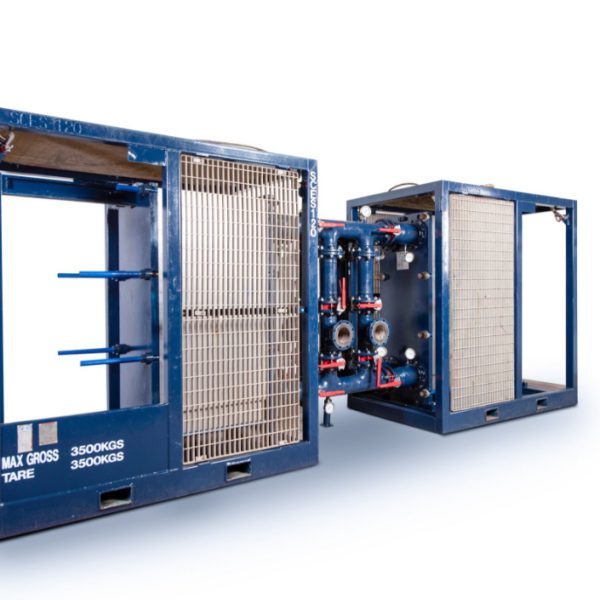

Following a stringent pre-project process, we leveraged our decanter centrifuge and disc stack centrifuge technologies, to treat and separate over 4,540 cubic meters of waste sludge which had been pumped from the tank, including naturally occurring radioactive materials, water, solids, and recoverable oil.

“ …the total savings and value recovered from the project are estimated to be in the millions, with only 200 tonnes of waste ultimately requiring off-site disposal at an estimated cost of £120,000.”

RESULTS

This enabled the on-site disposal of over 3,060 cubic meters of water through an effluent treatment plant, saving a seven-figure sum in disposal costs and minimising carbon emissions from waste transportation. Crucially, it enabled the recovery of approximately 1,280 cubic meters of oil, valued at around £450,000.

Consequently, the total savings and value recovered from the project are estimated to be in the millions, with only 200 tonnes of waste ultimately requiring off-site disposal at an estimated cost of £120,000.

• Separated 4,540 cubic metres of waste sludge

• On-site disposal greater than 3,060 cubic metres

• Generated seven figure savings

• Recovered approximately 1,280 cubic metres of oil

• Recovered oil valued at £450,000

CONTACT OSSO

Got a question

about a project?

Related Case Studies

Geothermal drilling achieving a 25% temperature reduction

- 25% temperature reduction

- Full-service maintenance contract

- Annual equipment swap out and refurb programme

Improve drilling efficiencies in high temperature wells.

- Reduced days drilling NPT per section drilled

- 40% decrease in round trips per section drilled

- 95% reduction in tool DBR