CASE STUDY

Diesel Polishing/ Treatment

Oil & Gas

CLIENT

Fairfield Energy

LOCATION

UKCS

SERVICES

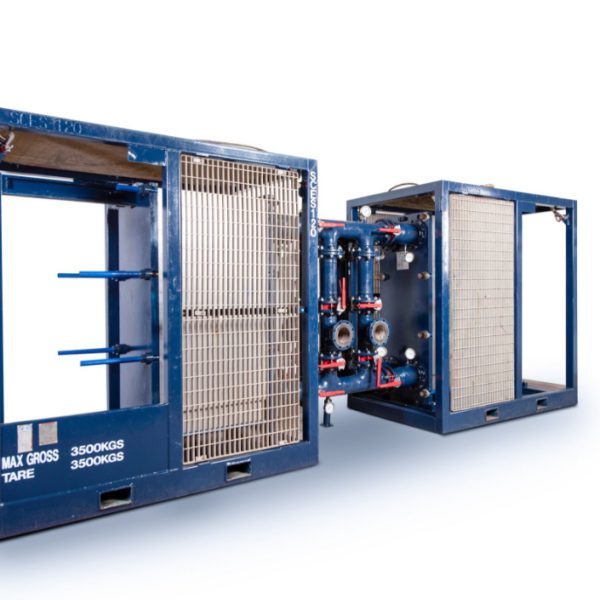

Mechanical separation - Fuel Treatment

THE CHALLENGE

As part of a North Sea platform's decommissioning scope, the designated waste management business commissioned OSSO to create a solution that would maximise fuel economy and minimise disposal costs by decontaminating large amounts of diesel to a quality level that would allow for reuse.

HOW WE HELPED

OSSO deployed a mechanical separator and specialist technicians offshore and worked in conjunction with ANSS. Based on a rotational shift we were able to continuously process the diesel providing maximum efficiency and production time without any lost time. The combined shift rotation with non stop processing enabled the work to be completed in eleven days without incident. For full transparency progress reports with fluid analysis results were provided daily to the client.

“We engaged with OSSO for assistance with a fuel recovery solution during a decommissioning project for a valued customer. The laydown area was particularly tight and had restricted access. The team at OSSO carefully considered the restrictions and provided a solution. We were invited along with the customer to the OSSO facility to meet their expert team and to demonstrate the equipment for this project. The team offshore were excellent and the equipment performed above expectation with more fuel being recovered than first anticipated but still within the original timescale. We look forward to working with OSSO on future decommissioning projects”

Project Engineer Specialist Cleaning

RESULTS

The total project lasted 20 days, 11 of which was offshore. During this time we extended the platforms operating efficiency by successfully processing 61.5 cubic meters of diesel, thus eliminating any disposal costs or repurchase of diesel equating to a saving of more than £45K.

- Extended platform operating efficiency

- Processed 61.5 cubic meters of diesel

- Provided continuous, round the clock processing

- Polished the diesel to a high enough quality that it was reused

CONTACT OSSO

Got a question

about a project?

Related Case Studies

Geothermal drilling achieving a 25% temperature reduction

- 25% temperature reduction

- Full-service maintenance contract

- Annual equipment swap out and refurb programme

Improve drilling efficiencies in high temperature wells.

- Reduced days drilling NPT per section drilled

- 40% decrease in round trips per section drilled

- 95% reduction in tool DBR